Laser cleaning of soot on non-porous materials

Removing soot and combustion residue is a delicate operation, particularly when it comes to preserving the original appearance of materials or restoring sensitive surfaces such as walls, ceilings, stone, beams, or decorative elements. These deposits are often stubborn and can affect both the aesthetics and integrity of the surfaces if not treated carefully.

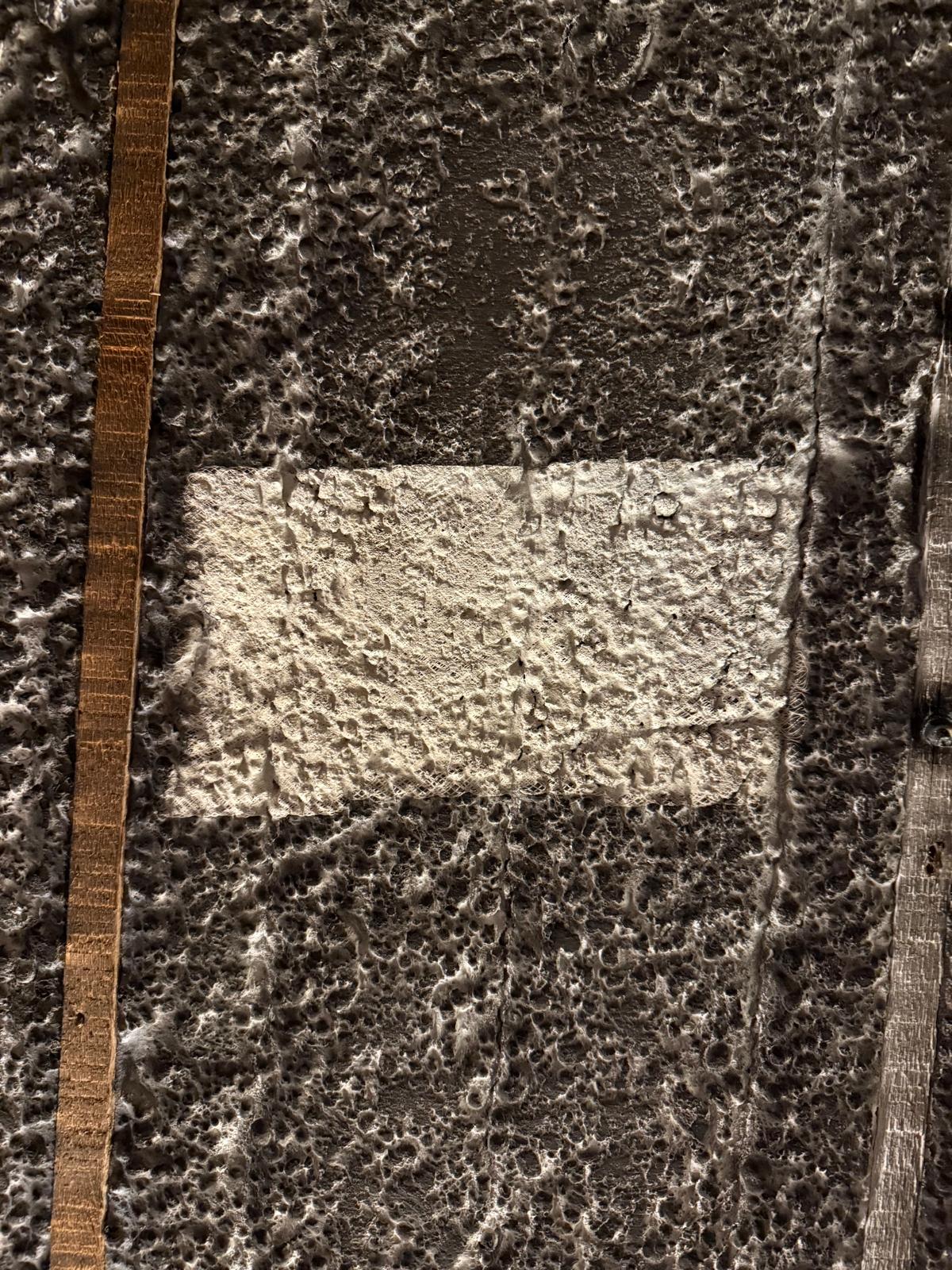

Laser stripping is an innovative, effective, and non-invasive solution for this type of intervention. Using an ultra-precise light beam, the laser removes surface combustion residue without damaging the underlying materials. This process uses a targeted thermal pulse, vaporizing the particles without mechanical contact, abrasion, or chemicals, and without generating liquid waste. The result is intensive, controlled cleaning that preserves the original finishes.

This technology is particularly suited to complex or fragile surfaces, often found in damaged buildings, industrial premises, or heritage buildings. Laser cleaning excels where other methods struggle to reach corners: reliefs, cracks, angles, moldings, vaulted ceilings, or ornate structures.

Please note that laser cleaning offers excellent results on many materials such as stone, wood, metal, brick, and certain coatings. However, on heavily damaged or highly porous surfaces, or when the residue is deeply embedded in the material, its effectiveness may be partially reduced. A preliminary technical assessment is therefore essential to determine the best cleaning strategy.

Are you facing soot damage or a disaster? Contact us to discuss your project and offer you a suitable, safe, and environmentally friendly solution.